We help create a lower carbon footprint and a more sustainable process industry

7726 kTONS

of CO2

has already helped

to save 7726 kilotons

of CO2

1000+

energy

projects

PDC executed

over 1000 projects, accumulating

up to 50

Gigawatts

1000+

reviews

PDC

has performed

over 1000

independent third-

party reviews

36

years

PDC has been

active for 36 years

as a leading

consultant in the process

industry

75%

doctorates

75% of PDC’s

employees hold

a doctorate degree

in their field

of expertise.

Up to 50%

cost

savings

PDC has

proven able

to generate capital

and operating

cost savings of up

to 50%

210 million

euros R&D

The total value

of PDC’s

collaborative R&D projects amounts

to 210 million

euros

50% bio-based

& circular

Bio-based and

circular process developments represent 50%

of PDC’s process

work

our finger print

PDC has a winning mentality and a go-getter attitude in supporting our process industry to do better. We like to go further when others are giving up…

Lighthouse projects

Smart-DAC

PDC is one of the founders of CO2CirculAir B.V., a new direct air capture (DAC) start-up…

read more +

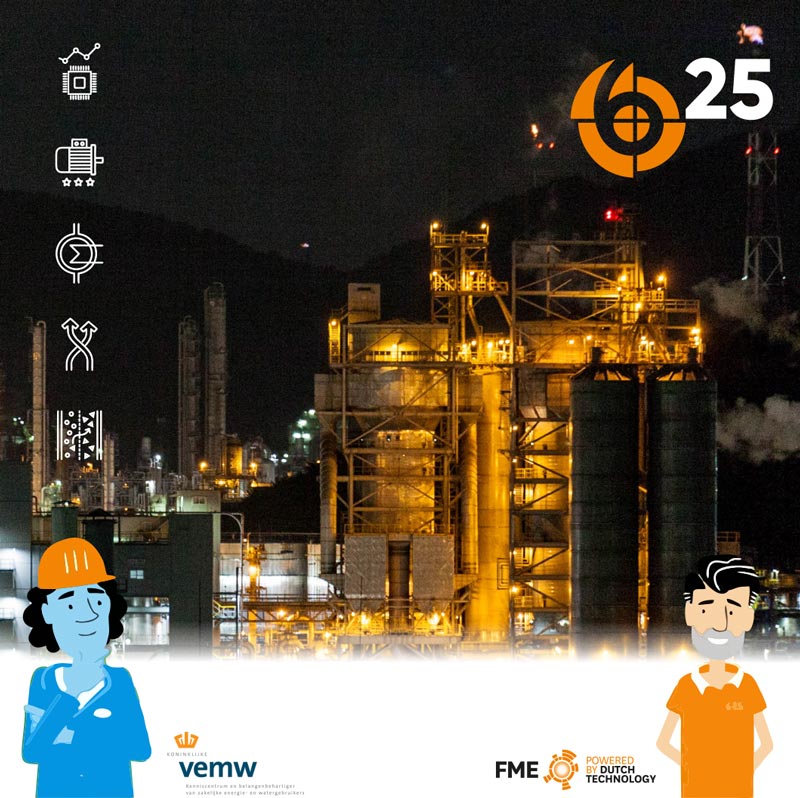

Project 6-25

PDC leads the project selection, definition, and guidance of Project 6-25, which aims to reduce an additional six million tons of CO₂ emissions in Dutch industry…

read more +

Redesigns for Shell

Already in the 1990s PDC created lower carbon footprint designs for Shell…

read more +

Biorefinery

To date PDC developed and evaluated 16 alternative integrated biorefining processes, based on enzymatic…

read more +

PROSYN® membranes

PROSYN® Membranes is the world’s first Artificial Intelligence-based system for the selection and design of membrane separation processes…

read more +

CLIENT’S EXPERIENCES

Martin Atkins,

FORMER CHIEF SCIENTIST AT BP IN CHINA AND CHIEF TECHNOLOGIST AT PETRONAS IN MALAYSIA AND CURRENTLY CEO OF GREEN LIZARD TECHNOLOGIES AND CTO OF POSEIDON PLASTICS IN THE UK.

LinkedIn

We have worked with PDC for over 20 years now with various partners in the Oil & Gas, bio, clean energy and chemicals/fuels sectors.

PDC have helped us enormously with conceptual design studies and understanding competitive technologies, providing appraisal and TEA data in the same package to help our businesses strategies and make best decision for commercial design. The option to use PDC team throughout the development cycle as well really enhances option development and energy savings in order to “fix” the design to allow basic engineering packages to be developed for use with PDC. Working early with PDC at conceptual and TEA study has taken considerable amount of time off the path to commercialization. In some cases, the work with PDC has led us to stop projects early and prevent the team going down dead ends”.